Steam Valves

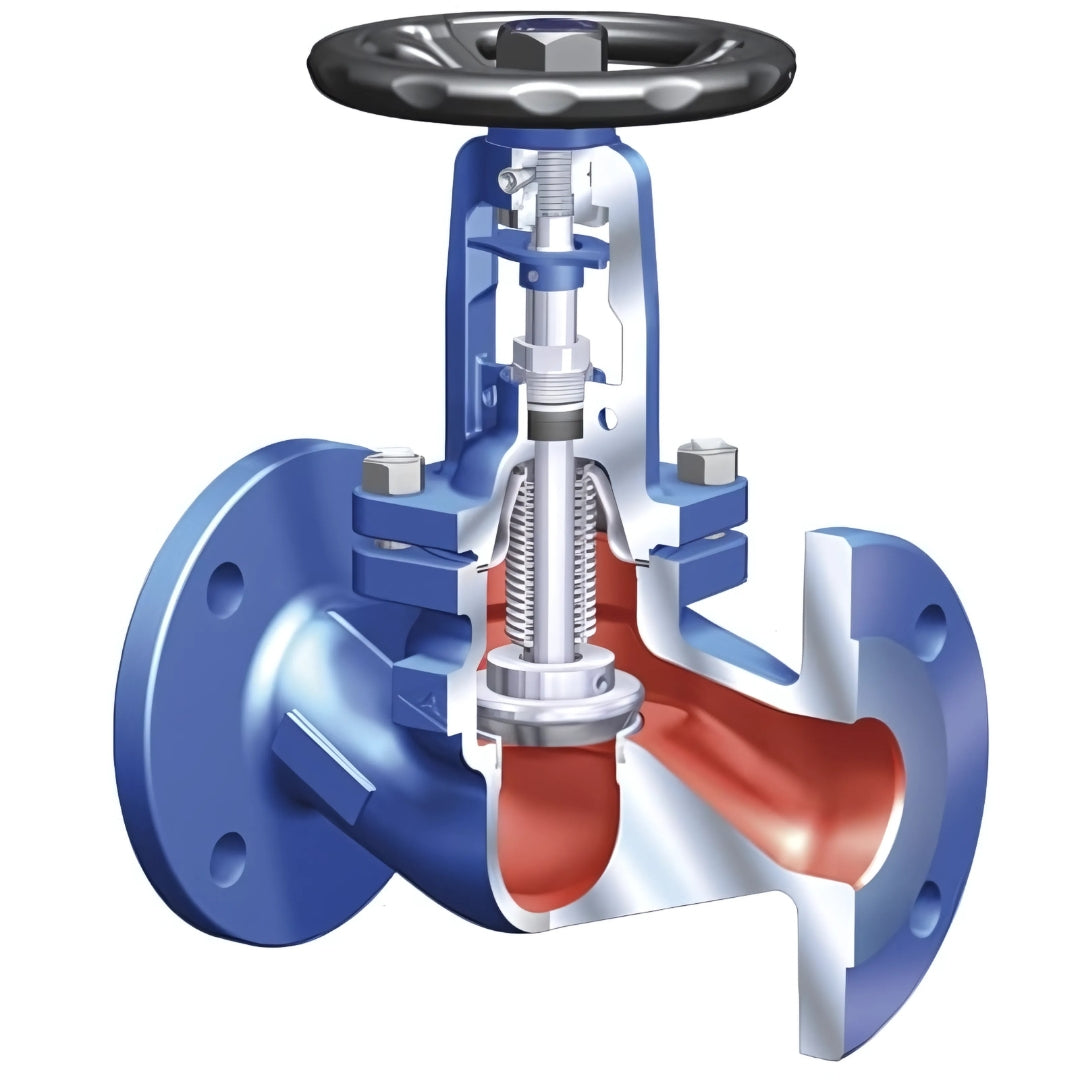

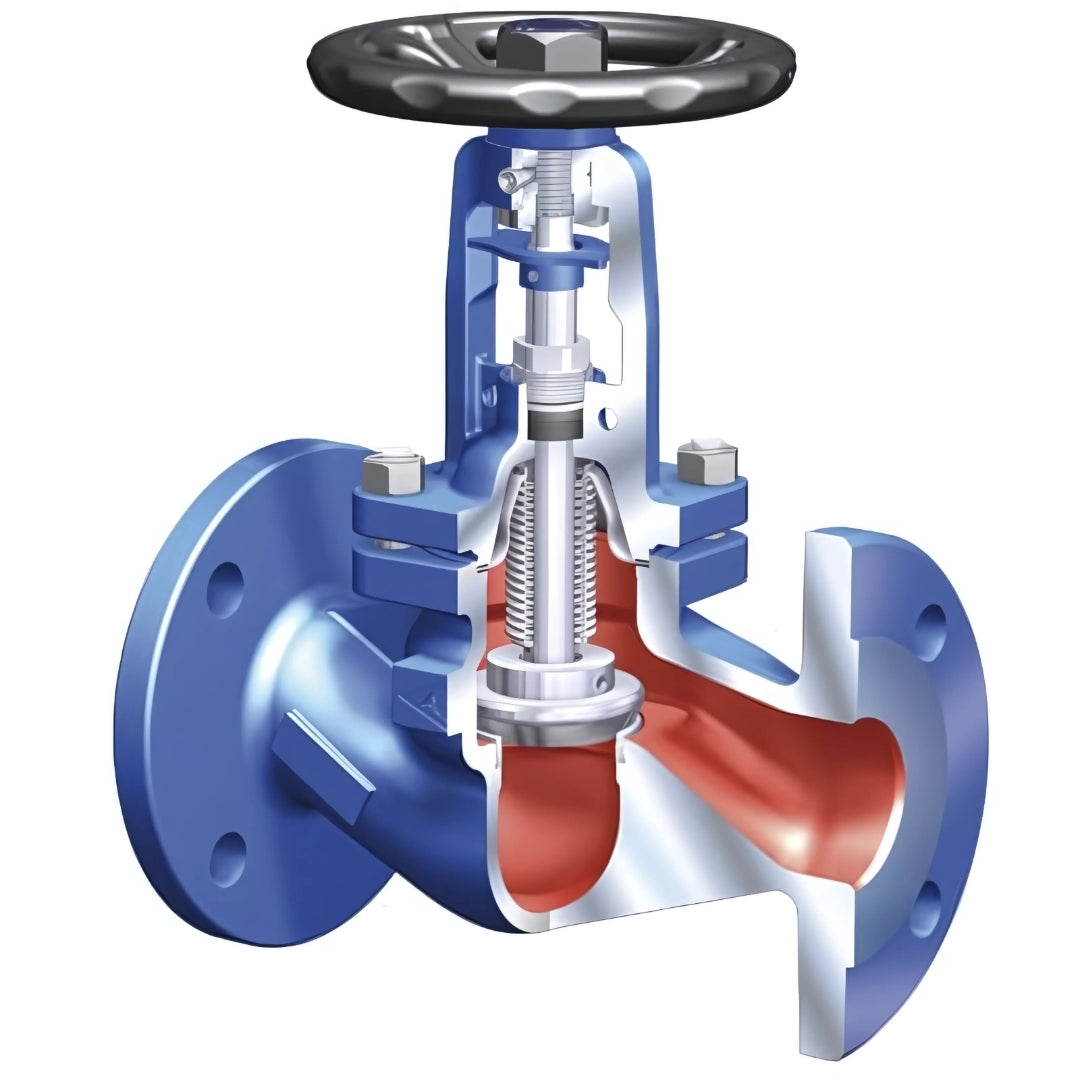

FABA+ Bellows Sealed Globe Valve (Flanged PN16, Nodular Iron Body)

FABA+ Bellows Sealed Globe Valve (Flanged PN16, Nodular Iron Body)

Couldn't load pickup availability

The FABA+ Bellows Sealed Globe Valve with PN16 flanged ends and a nodular cast iron body is designed for safe, efficient, and leak-free operation in low-to-medium pressure steam, condensate, and fluid handling systems. Engineered with a multi-layer stainless steel bellows seal, this valve provides a completely sealed stem design — eliminating fugitive emissions and protecting both personnel and the environment.

Constructed from nodular (ductile) cast iron, the body offers excellent toughness, pressure resistance, and thermal stability, making it ideal for heating circuits, building services, and light-duty industrial applications. The PN16 pressure rating allows for safe operation in systems up to 16 bar. The rising stem with an integrated backseat adds a secondary sealing layer when fully open, allowing safe gland packing maintenance. With its linear globe-style flow path, the valve offers accurate throttling control and dependable shut-off performance.

Part of the ARI Armaturen FABA+ range, this valve delivers a balance of performance, safety, and value in applications where reliability and emission control are key.

Key Features

Nodular Iron Body

Durable and resilient material with excellent shock absorption and fatigue resistance.

PN16 Flanged Ends

Rated for low-to-medium pressure pipelines operating up to 16 bar.

Bellows Sealed Stem

Eliminates stem leakage, ensuring emission-free operation for steam and process media.

Backseat Design

Provides additional sealing protection when the valve is fully open — ideal for safe maintenance.

Globe Valve Flow Control

Linear movement for smooth throttling and precise shut-off.

Proven in Utility Systems

Widely used in HVAC, district heating, building management systems, and clean steam applications.

Share

FAQ's

What is the difference between a valve and an actuator?

What types of actuators are available?

The main types of actuators are:

Pneumatic actuators – use compressed air for fast, reliable operation.

Electric actuators – use electrical power for precise control.

Hydraulic actuators – use fluid pressure for high-torque applications.

Each type offers unique advantages depending on the environment, media, and system control needs.

How do I choose the right actuator for my valve?

To select the correct actuator, consider:

Valve type and torque requirement

Power source available (air, electric, or hydraulic)

Operating environment (temperature, humidity, hazardous area)

Control signal type (on/off or modulating)

Matching actuator torque and compatibility with the valve’s ISO mounting ensures reliable performance.

What are the main types of valves used in automation?

The most common valves in automated systems include:

Ball valves – for tight shutoff and quick operation.

Butterfly valves – for larger flow control with compact design.

Globe valves – for precise throttling and flow regulation.

Check valves – to prevent backflow.

Gate valves – for full bore flow isolation.

What’s the difference between a double-acting and spring-return actuator?

Double-acting actuators use air (or power) to both open and close the valve.

Spring-return actuators use air to open (or close) the valve, and a built-in spring to automatically return it to a safe position when power or air is lost — ideal for fail-safe operation.

How often should valves and actuators be serviced?

Regular maintenance intervals depend on operating conditions, but a good rule of thumb is to inspect every 6–12 months.

This includes checking for leaks, lubrication, seal wear, and actuator responsiveness to prevent unexpected downtime.