Valves UK

Max-Air MT30-0DAD31 Double Acting Pneumatic Actuator

Max-Air MT30-0DAD31 Double Acting Pneumatic Actuator

Couldn't load pickup availability

IN STOCK - SAME DAY DISPATCH

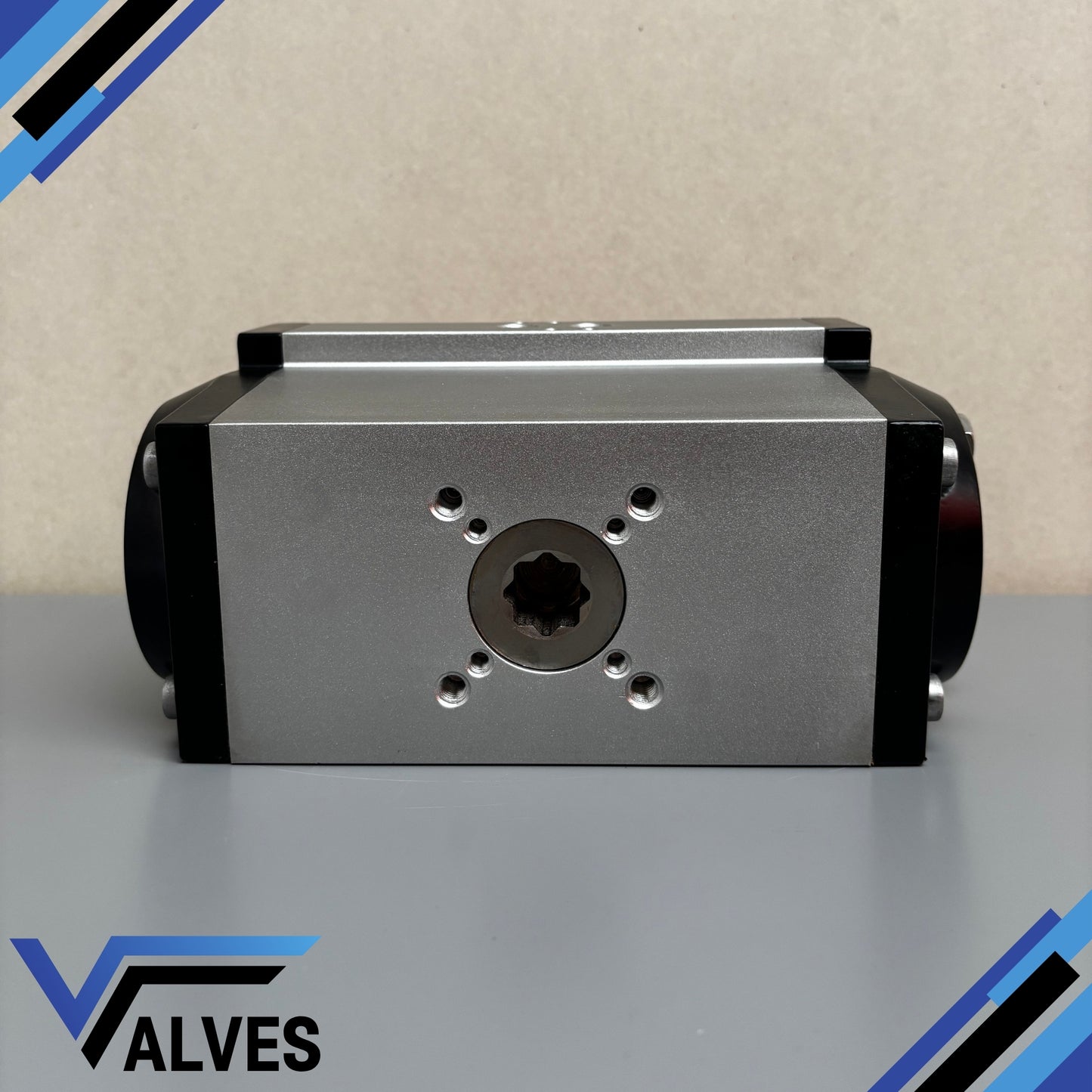

The Max-Air MT30-0DAD31 is a high-performance rack-and-pinion pneumatic actuator engineered for quarter-turn valve automation (ball, butterfly, plug) in demanding process environments. Built within the MT Series platform, this double-acting version (air to open / air to close) delivers robust 120 Nm torque (at approx. 6 bar supply), mounts via ISO 5211 / F05–F07 pad and is certified for use in hazardous atmospheres via ATEX “II 2 GD” classification.

Designed with an anodised aluminium body, external travel stops and all-steel pinion drive, the MT30 unit provides reliable, repeatable operation in rugged conditions. The modular design supports direct mounting of NAMUR solenoid valves or limit switches, simplifying integration and reducing installation time. Whether utilised in petrochemical, water treatment, power, or other industrial plants, this actuator offers a balance of compact size, high torque, and global safety certification.

Key Features

Double Acting (Air Open / Air Close) – Enables full 90° quarter-turn control without reliance on a spring-return mechanism.

Torque Output ~120 Nm at ~6 bar – Suitable for moderate duty valves requiring high torque in a compact unit. (Data table shows MT30 at ~100-120 Nm at 6 bar)

Supply Pressure Around 6 bar (10 bar max variant available) – The MT Series supports operation typically 2-10 bar as standard.

Operating Temperature Range –20 °C to +80 °C (standard seals) – With standard Buna-N seals; higher or lower temperature options available.

ATEX Certified II 2 GD (Zone 1/21 & Zone 2/22) – The MT Series benefits from ATEX certification for use in explosive gas/dust atmospheres.

ISO 5211 / Namur / F05–F07 Mounting Footprint – Enables direct installation on standard quarter-turn valves and interface blocks.

Hard-anodised extruded aluminium body with epoxy-coated cast aluminium end caps – Provides corrosion resistance and durability in industrial service.

Rack & Pinion mechanism with anti-blowout pinion design – Ensures reliable torque output and safety under cyclic operations.

±10° adjustable travel stops (for sizes MT15 up) – offering fine tuning of 70°-110° stroke if required – Patent feature in MT series.

High-cycle design, permanent lubrication, stainless steel external fasteners – Minimises maintenance and supports long term reliability.

Share

Enquire Online!

FAQ's

What is the difference between a valve and an actuator?

What types of actuators are available?

The main types of actuators are:

Pneumatic actuators – use compressed air for fast, reliable operation.

Electric actuators – use electrical power for precise control.

Hydraulic actuators – use fluid pressure for high-torque applications.

Each type offers unique advantages depending on the environment, media, and system control needs.

How do I choose the right actuator for my valve?

To select the correct actuator, consider:

Valve type and torque requirement

Power source available (air, electric, or hydraulic)

Operating environment (temperature, humidity, hazardous area)

Control signal type (on/off or modulating)

Matching actuator torque and compatibility with the valve’s ISO mounting ensures reliable performance.

What are the main types of valves used in automation?

The most common valves in automated systems include:

Ball valves – for tight shutoff and quick operation.

Butterfly valves – for larger flow control with compact design.

Globe valves – for precise throttling and flow regulation.

Check valves – to prevent backflow.

Gate valves – for full bore flow isolation.

What’s the difference between a double-acting and spring-return actuator?

Double-acting actuators use air (or power) to both open and close the valve.

Spring-return actuators use air to open (or close) the valve, and a built-in spring to automatically return it to a safe position when power or air is lost — ideal for fail-safe operation.

How often should valves and actuators be serviced?

Regular maintenance intervals depend on operating conditions, but a good rule of thumb is to inspect every 6–12 months.

This includes checking for leaks, lubrication, seal wear, and actuator responsiveness to prevent unexpected downtime.