Wras Valves

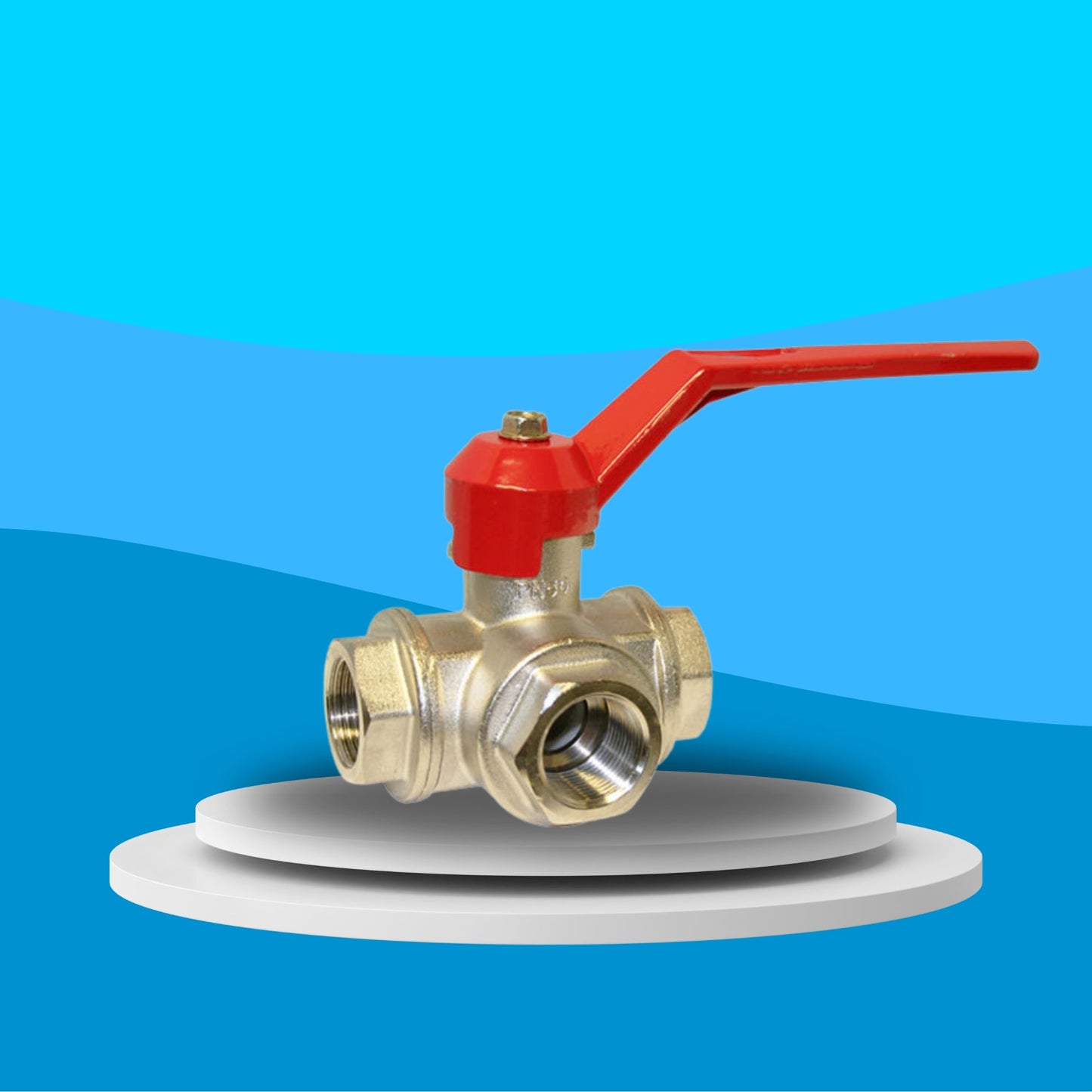

Wras Approved Brass Ball Valve - 3 Way T Port - Screwed BSPP (Red Lever Operated)

Wras Approved Brass Ball Valve - 3 Way T Port - Screwed BSPP (Red Lever Operated)

Couldn't load pickup availability

WRAS Approved | 3-Way T Port | BSPP Threaded Ends | Full Bore | Red Lever Handle

The WRAS Approved Brass 3-Way T Port Ball Valve with Screwed BSPP ends is a robust and adaptable valve solution for distributing or combining flow within potable water systems. Featuring a T Port configuration, this valve allows simultaneous flow between any two or all three ports, making it ideal for blending, diverting, or loop systems where flexible flow paths are essential.

Manufactured from durable brass and fully WRAS certified, this valve is approved for use with potable water applications in both domestic and commercial environments. The full bore design ensures optimal flow with minimal pressure drop, supporting efficient system performance even in high-demand installations.

With BSPP threaded ends, the valve fits seamlessly into standard threaded pipework, while the red lever handle provides simple manual control and easy visual identification. Built for longevity and performance, this 3-way valve offers reliable operation across a wide range of water and fluid handling systems.

WV - 5310 T

Share

FAQ's

What is the difference between a valve and an actuator?

What types of actuators are available?

The main types of actuators are:

Pneumatic actuators – use compressed air for fast, reliable operation.

Electric actuators – use electrical power for precise control.

Hydraulic actuators – use fluid pressure for high-torque applications.

Each type offers unique advantages depending on the environment, media, and system control needs.

How do I choose the right actuator for my valve?

To select the correct actuator, consider:

Valve type and torque requirement

Power source available (air, electric, or hydraulic)

Operating environment (temperature, humidity, hazardous area)

Control signal type (on/off or modulating)

Matching actuator torque and compatibility with the valve’s ISO mounting ensures reliable performance.

What are the main types of valves used in automation?

The most common valves in automated systems include:

Ball valves – for tight shutoff and quick operation.

Butterfly valves – for larger flow control with compact design.

Globe valves – for precise throttling and flow regulation.

Check valves – to prevent backflow.

Gate valves – for full bore flow isolation.

What’s the difference between a double-acting and spring-return actuator?

Double-acting actuators use air (or power) to both open and close the valve.

Spring-return actuators use air to open (or close) the valve, and a built-in spring to automatically return it to a safe position when power or air is lost — ideal for fail-safe operation.

How often should valves and actuators be serviced?

Regular maintenance intervals depend on operating conditions, but a good rule of thumb is to inspect every 6–12 months.

This includes checking for leaks, lubrication, seal wear, and actuator responsiveness to prevent unexpected downtime.